The Biden Administration’s Offshore Wind Fantasy

Introduction

President Biden has set a goal of 30,000 megawatts (MW) of offshore wind turbines by 2030 [1] and 110,000 MW by 2050. [2] The administration claims that the 30,000-MW target will create thousands of new jobs and avoid 78 million tons of carbon dioxide emissions each year. [3] (By comparison, total U.S. carbon dioxide emissions in 2019 were about 5 billion metric tons). [4] Regardless of whether these claims are accurate (they are not), this new offshore wind target is yet another in a series of unworkable and unaffordable green fantasies that have been adopted here in the U.S. and in Europe.

As this report will demonstrate, the realities of offshore wind planning, development, and construction render the president’s goal unachievable. A single offshore wind project can easily take longer than a decade to develop. Although numerous projects scheduled to be built before 2030 have been announced in the last decade (see Figure 1), only one—the 800-MW Vineyard Wind project, to be built off the Massachusetts coast south of Martha’s Vineyard—has begun preliminary construction. And that project is facing at least three lawsuits that are sure to delay its completion. [5]

Even if the president’s goal were physically achievable, it should not be pursued because of offshore wind’s dismal economics. Offshore wind is hugely expensive, much more so than solar, onshore wind, hydropower, and geothermal. [6] And despite proponents’ claims to the contrary, the costs of installing offshore wind facilities are not decreasing. Furthermore, economic and physical constraints are likely to raise the costs of offshore wind projects, as developers compete for scarce resources. [7] Moreover, because it is inherently intermittent—producing electricity only when the wind blows—offshore wind will require significant investment in backup supply resources, primarily gas- and oil-fired generators, to compensate for the more than 50% of all hours when the wind is not blowing. Although wind and solar proponents claim that battery storage will eliminate the need for fossil-fuel backup generation, the costs, raw-materials requirements, and manufacturing capacity needed to produce the quantity of battery storage that is needed to provide even three or four hours of backup power would be staggering.

There is only one offshore wind facility operating in the U.S. today—the five-turbine, 30-MW Block Island Wind Farm, located off the coast of Rhode Island. The project took two years to build and cost about $300 million. The 22-mile-long Sea2Shore transmission line that brings the electricity from Block Island to the mainland cost another $114 million. [8] Thus, the overall project cost was over $400 million—over $13 million per MW. (By comparison, a new gas-fired combined-cycle generator has a capital cost of about $1 million per MW, and new offshore wind projects have an estimated capital cost of about $5.5 million per MW.) [9]

The Block Island Wind Farm exemplifies the types of technological issues that are almost certain to affect future U.S. offshore wind development. Since it began producing electricity in December 2016, Block Island has been plagued by operational issues: in 2017, both the undersea cables that deliver electricity from the turbines became uncovered because of tidal action. After almost five years, the Sea2Shore cable still has not been reburied. Most recently, in June 2021, potential stress fractures were found in four of the five towers that support the turbines. Although Ørsted, the project developer, shut down the turbines for “routine maintenance,” at least three of the five turbines were still off-line as of November 2021. [10]

Offshore wind development in the U.S. also faces significant environmental pushback, including from commercial and sport fisheries interests. As development accelerates, offshore wind projects will face growing logistical and supply issues. Together, these will delay development and increase costs, contrary to the pipe-dream projections of ever-decreasing offshore wind costs. Moreover, the ever-increasing offshore wind goals of European countries, as well as China, will exacerbate the logistical and supply issues faced by offshore wind developers in the United States.

Figure 1.

Proposed Offshore Wind Developments

Source: Bureau of Ocean Energy Management

The Realities of Offshore Wind Project Development

The newest and largest offshore wind turbines can generate about 14 MW each. Meeting the president’s goal, therefore, would require installing more than 2,200 such turbines over the next nine years, or almost 250 every year. That translates to installing one turbine every 32 hours for the next nine years, along with all the required undersea cables and onshore equipment needed to deliver the electricity generated by offshore wind projects to the mainland, as well as the investments needed to integrate that electricity into the high-voltage power grid.

Developing a single offshore wind project—from project conception to completion of construction and final testing—can take a decade or longer. After completing preliminary project plans, developers have to bid on and secure offshore leases—large undersea plots of land where the turbines can be built. They must then prepare detailed construction and operation plans (COPS), which must be approved by the Bureau of Ocean Energy Management (BOEM), as part of an overall environmental review process. BOEM also has to produce a detailed environmental impact statement (EIS) for the project and handle the inevitable legal challenges to the agency’s findings. Developers must also secure financing for their projects, which can take several years and require detailed analyses and projections of future revenues and costs.

Only after environmental permits and financing are secured (and assuming that there is no subsequent litigation) can construction begin. Based on experience in Europe, construction for a typical 800–1,000-MW project will take at least three years to complete, assuming no delays. This includes the time needed to build the onshore infrastructure where the electricity will be delivered and the installation of the turbines themselves.

To better understand the entire development process, Figure 2 shows the initial timeline, including the schedule assumed in the COP, for the Vineyard Wind Project. [11] The project was first conceived in 2009, and the actual project development process began in June 2014, when BOEM allowed potential developers to start to bid on offshore leases. The Vineyard Wind developers estimated that the project would be completed sometime in the third quarter of 2023

After a developer has secured an offshore lease, usually based on competitive solicitations undertaken by BOEM, the developer submits a detailed COP. The COP for Vineyard Wind was submitted on December 19, 2017. [12]

After a developer submits its COP, BOEM issues a notice of intent (NOI) to prepare a Draft Environmental Impact Statement (DEIS). [13] For Vineyard Wind, BOEM issued this NOI on March 30, 2018. The NOI allowed a 30-day public comment period, during which time BOEM held public meetings. BOEM then issued its scoping report and began work on the DEIS. BOEM published the Vineyard Wind DEIS on December 7, 2018. [14] The DEIS was then subject to public comment. In the case of Vineyard Wind, based on those public comments, BOEM performed additional environmental analysis; 18 months later, in June 2020, it issued a supplement to the DEIS. [15] Nine months after comments were received by BOEM on the supplemental DEIS, the agency issued its final EIS for Vineyard Wind, in March 2021. Finally, on July 15, 2021, BOEM approved the Vineyard Wind COP. [16] Thus, the environmental review process alone for Vineyard Wind took approximately three and a half years.

As offshore wind projects expand, the cumulative environmental impacts of those projects, especially on commercial and sport fisheries and migratory species, will become more important to evaluate. The process will thus become even more complex and time-consuming. And even after BOEM approves a COP, litigation can delay a project. Three lawsuits already have been filed against Vineyard Wind, two of which allege harm to endangered whales. [17] The other, filed by the Responsible Offshore Development Alliance (RODA), a coalition of fishing industry groups, alleges that BOEM’s approval of the project “adds unacceptable risk” to the fishing industry. [18] Whatever one thinks about the legitimacy of such legal challenges, which are common for many types of energy infrastructure projects (e.g., pipelines, high-voltage transmission lines, solar farms), they can delay projects for many years.

An approved COP is just one component of the regulatory review process. In addition to passing environmental muster, projects must secure siting approval from state energy and environmental regulators for onshore facilities and submit to a detailed review of how the highvoltage transmission grid must be modified to manage the electricity that will be generated by the project. If the transmission grid requires new projects to be constructed, such as new highvoltage transmission lines, those must be approved by the Federal Energy Regulatory Commission.

Even if the recent lawsuits are quickly resolved, Vineyard Wind will not be finished until 2024, at the earliest, 15 years after the project was first conceived.

Figure 2.

Vineyard Wind Project Initial Development Timeline

Mainland Transmission Interconnection Requirements

Commercial power facilities cannot simply be “plugged into” the high-voltage transmission grid. Instead, new generation facilities must undergo detailed system-impact studies to ensure that their output can be accommodated by the transmission grid without causing instability that could lead to forced outages. The studies also evaluate the reliability impacts of the project—that is, the likelihood that a sudden outage of the facility or the interconnections will cause a blackout. Typically, upgrades to the transmission system are required to accommodate the additional generation.

ISO New England (ISO-NE), which operates the high-voltage transmission system in the New England states and coordinates the operation of all generating plants, has begun preparing a Cape Cod Resource Integration Study. The first phase of that study evaluated Vineyard Wind and the 800-MW Mayflower Wind project, both of which will be built southwest of Nantucket. [19] The study determined that connecting the Mayflower Wind project will require a new 345-kilovolt (kV) substation at Bourne, Massachusetts, and a new 345-kV transmission line from West Barnstable, Massachusetts, to Bourne. The estimated total cost for the required transmission-system upgrades is $335 million, which will be paid for by New England electric ratepayers. [20]

Integrating offshore wind into the power grid requires more than just building new transmission-system infrastructure, however. Transmission-system planners must also determine the amount of reserve capacity—whether generators on standby or large-scale storage batteries— that will be needed to meet U.S. government reliability standards. [21] Wind power is not only inherently intermittent, but—unlike many fossil-fuel generators—wind turbines cannot “load follow,” that is, ramp their output up or down in response to instantaneous changes in overall electricity demand. Maintaining a reliable grid, therefore, requires backup generation to “firm up” those facilities’ output. Typically, this means having more gas-fired generators operating on standby. (Think of this as equivalent to a car engine idling so that it can drive off immediately, if needed.)

The amount of reserve capacity, called “Installed Reserve Margin” (IRM), needed to integrate large amounts of intermittent wind and solar generation is substantial. Consider, for example, New York State, which passed legislation in 2019 mandating a “zero-emissions” electric system by 2040. According to the New York State Reliability Council (NYSRC), the projected peak electricity demand in 2040 will be about 38,000 MW and will require 50,000 MW of reserve capacity in order to maintain reliability. Currently, the state needs only 6,600 MW of reserve capacity. [22]

In other words, the IRM would be well over 100%, as opposed to the 20% margin today. One obvious consequence of a fivefold increase in the IRM would be higher electricity costs because owners of that reserve capacity would have to be compensated sufficiently to stay in business.

Most ominously, NYSRC concluded that maintaining reliability would require “substantial clean energy and dispatchable resources, some with yet to be developed technology, over and above the capacity of all existing fossil fuel resources that will be replaced.” [23]

NYSRC is a nonpartisan state agency whose mission is to ensure that New York’s electric power system provides state residents and businesses with adequate electricity supplies at all times. As electrification mandates, including those for the purchase of electric vehicles, increase the demand for electricity, ensuring reliable supplies of electricity will become that much more important for the U.S. economy. But if ensuring such reliability requires yet-to-be-invented technologies, then U.S. energy policy, including green energy mandates, is completely divorced from reality.

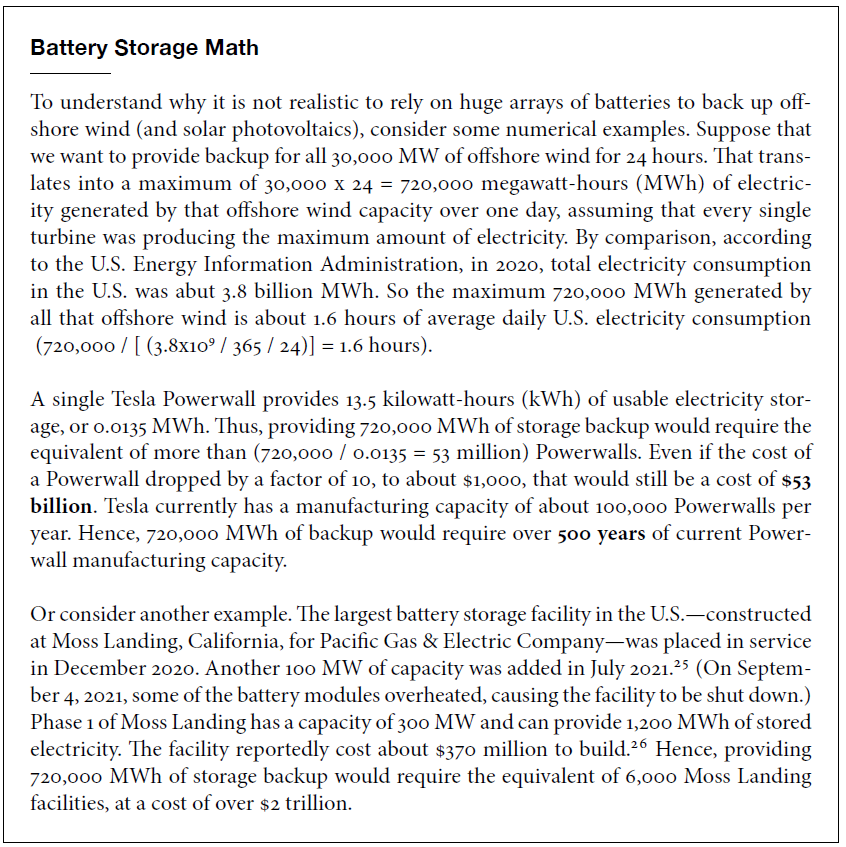

Claims that enough battery storage can be deployed to ensure reliable electric supplies are also unrealistic. As Manhattan Institute fellow Mark Mills has shown, the quantities of raw materials needed for large-scale battery manufacture are staggering. [24] Moreover, one would need to build the equivalent of hundreds of Tesla “gigafactories” to produce sufficient numbers of storage batteries to provide even a few hours of backup power for 30,000 MW of offshore wind (see sidebar, Battery Storage Math).

The Realities of Offshore Wind Construction

Even if there are no legal challenges causing delays, actual construction of an offshore wind project and the transmission infrastructure (undersea cables, on-land substations, new high-voltage transmission lines) needed to deliver the electricity that it will produce to the bulk power system is complex and time-consuming.

For example, as shown in Figure 2, the assumed construction period for Vineyard Wind is about three years. [27] Installing the foundations is expected to take at least six months, and installing the turbines is expected to take at least one year. That translates into about 18 months to install 62 14-MW turbines, or about one turbine every nine days. But numerous issues, affecting everything from manufacturing the turbines to installing them, are likely to cause project delays, especially as the number of projects increases.

Materials Issues

The promised surge in offshore wind development will run headlong into the reality of scarce resources. The raw materials needed for these projects are expensive and already in short supply.

Many offshore wind proponents ignore these issues, preferring instead to present rosy press releases that promise lower installation costs and a green economic nirvana. For example, a 2021 article in Nature Energy claims that offshore wind costs will decline by as much as half by 2050, based on nothing more than the opinions of “experts.” [28] A report from the National Renewable Energy Laboratory claims that, by 2030, the levelized cost [29] of offshore wind will decrease to just $51/MWh. [30] By contrast, the U.S. Energy Information Administration (EIA) estimates a levelized cost of offshore wind facilities entering service in 2026 at $115/MWh. [31]

Whereas one may expect offshore wind developers to be cheerleaders for their projects, of greater concern is that many U.S. policymakers refuse to recognize these issues, with many adopting a head-in-the sand approach toward them or, worse, attacking those who raise the issues. [32] But like the fable of “The Emperor’s New Clothes,” the realities of offshore wind development will make themselves known, regardless of how much proponents wish to deny them.

Wind turbines, as well as solar panels and storage batteries, require rare-earth metals. Most of the rare earths required are sourced from China, which currently produces about 70% of global supplies. [33] As the demand for rare earths increases, including for batteries to power electric vehicles, supply shortages are likely because of the limited sources for supplies. [34] Currently, the U.S. has little mining capacity for rare earths, although a new mine in Hudspeth, Texas—the Round Top Heavy Rare Earth, Lithium, and Critical Minerals Project—which is being developed by USA Rare Earths, is scheduled to open sometime in 2023. [35]

The magnets that wind turbines use to generate electricity contain rare earths. But there is only one manufacturer of these magnets in the United States. It is located in North Carolina and produces about 2,400 tons of magnets annually. Boosting wind energy production—both onshore and offshore—will require far greater supplies of magnets. With the increase in demand and higher rare-earth prices, offshore wind manufacturing costs will similarly increase.

Supplies for other key inputs, such as steel used for offshore wind foundations and towers, are also in short supply; and prices have increased substantially. [36] Although some of these shortages have been driven by the Covid-19 pandemic and associated steel-mill shutdowns, post-pandemic increases in demand for automobiles will push steel demand higher. Thus, offshore wind projects will compete for scarce steel supplies, leading to project delays and higher costs.

Turbine Size and Installation Complexity

The newest iteration of offshore wind turbines—which are slated to be used in many offshore wind projects, including Vineyard Wind—have a generating capacity of about 14 MW. (The only such turbine in operation today is a GE Haliade demonstration turbine located on dry land in Rotterdam, which started operation in 2019.) The new GE turbines weigh 825 metric tons and stand 850 feet tall—about three times taller than the Statue of Liberty. [37]

Not to be outdone, the Danish company Vestas announced in October 2021 that it will install a 15-MW demonstration turbine in 2022, which will stand 280 meters (over 900 feet) tall. (A German energy company, EnBW, may use this turbine in 2025 for its proposed 900-MW wind farm.) [38] There are designs for even larger wind turbines, with generating capacities of 20 or even 25 MW, but it is unlikely that these larger turbines will be installed over the next decade because the laws of physics present unavoidable and difficult scaling issues. [39]

The 14-MW GE turbines have yet to be installed offshore in Europe. (The largest offshore turbines installed have been 10-MW ones, weighing about 500 tons.) Because they weigh 60% more than the largest installed turbines, the installation process for the 14-MW GE turbines will likely be complex and time-consuming until installers gain sufficient experience.

The installation process for these new turbines requires highly specialized and expensive ships— costing about $500 million each—called “wind turbine installation vessels” (WTIVS). WTIVS share characteristics with so-called Jackup Rigs used for offshore oil drilling. [40] Only 16 WTIVS are operating today. By 2023, just seven WTIVS in the entire world will be capable of installing turbines as large as the new GE and Vestas ones. However, those ships may not be permitted to install offshore wind turbines constructed in the U.S. because of a federal law, the Jones Act, that requires goods shipped between U.S. ports to be transported on vessels that are built, owned, and operated by U.S. citizens or permanent residents. The only Jones Act–compliant WTIV will be the $500 million Charybdis, scheduled for completion by late 2023. [41]

Because the Jones Act applies only to goods shipped from U.S. ports, the only alternative will be to install offshore wind turbines that have been built abroad. Of course, this would conflict with the administration’s promise of thousands of new domestic manufacturing and installation jobs. Moreover, global competition for the use of those ships by offshore wind developers will be intense, especially as European countries continue to increase their offshore wind portfolios. If anything, as the demand for these vessels increases, the cost to lease them is likely to increase, raising project costs. In the North Sea, for example, the success of offshore wind installation is due largely to the expertise of oil companies that have installed offshore platforms there. And, while there is significant expertise in offshore oil rigs along the U.S. Gulf Coast, there is no experience off the Atlantic Coast. Thus, not only will the supply of qualified personnel to operate WTIVS be constrained, but there will also be a learning curve associated with installing projects along the Atlantic Coast.

Undersea Cable Installation

Yet another challenge facing offshore wind developers is the installation of undersea cables that will deliver the electricity generated to mainland interconnections. As the experience with the offshore cable for the Block Island Wind Farm has demonstrated, improper burial of offshore cables is problematic. If the cables are set too shallow, as is the Block Island cable, they risk getting unburied by what is called “scour.” [42] Unburied cables offshore are hazardous because they can be snagged by draglines or even ship anchors. But burying cables too deep risks overheating, which reduces the amount of electricity that can be transmitted. [43]

The first requirement for offshore cable projects is siting, which requires numerous studies, including: (i) Preliminary Route and Landing Site Assessment; (ii) Cable Burial Risk Assessment (CBRA); and (iii) Cable Burial Feasibility Assessment. The CBRA is especially important, as it determines the minimum recommended depth to avoid fisheries risks. [44] In addition, most projects will require the undersea cables to undergo a separate permitting process. New York, for example, considers undersea cables operating at or above 125,000 volts major transmission facilities, and they must undergo a detailed siting process known as an “Article VII” process. [45] Virtually all large offshore wind developments will require cables operating at even higher voltages. [46]

Lack of cable manufacturing capacity is another issue that will delay offshore wind development. Lead times of several years for new undersea cable are common. [47] Under-capacity of cable manufacturing and installation is likely to increase as more offshore wind projects are developed, leading to project delays and higher costs. [48] Moreover, offshore cable must be installed using special ships called Cable Lay Vessels. The weight of offshore cable, about 240 tons per mile, [49] means that larger vessels are preferred; these vessels can carry longer lengths of cable, which means fewer cable segments and joints connecting them.

In Britain, the entire process for undersea cable planning and installation requires years of planning just to determine whether an offshore cable project is feasible and can be financed. Final installation and testing can take two to three years longer. [50] It is unlikely that the installation process in the U.S., which requires similar types of planning studies, detailed environmental review, and regulatory approvals, will be any faster.

The costs of inadequate cable siting and improper burial are substantial. In Europe, the wind industry reports that about 70% of all project insurance claims are the result of cable manufacturing defects, installation issues, and damage from external forces. Increasing competition in offshore wind has led to cost-cutting at the expense of quality control, and this is leading to more insurance claims.[51] More cable breakdowns mean even less power supplied, which will further increase the costs of ensuring reliability.

Pursuing the Offshore Wind Fantasy Will Impose Significant Costs but Few, if Any, Benefits

In 2020, total utility-scale electric generating capacity in the U.S. was over 1.1 million MW. Of that total, almost half, about 486,000 MW, was natural gas-fired generation. Another 215,000 MW was coal-fired generation.[52] By 2050, EIA projects that total U.S. generating capacity will be about 1.7 million MW, more than a 50% increase over current levels.[53] While EIA projects that coal-fired generation will decrease to just 125,000 MW by 2050, that is still four times the administration’s 2030 offshore wind goal. The single largest increase will be natural gas-fired generating capacity, which EIA projects at about 300,000 MW by 2050. What these data mean is that, even if it were physically achievable, the addition of 30,000 MW of offshore wind capacity by 2030 will represent a tiny fraction of total U.S. generating capacity. The 78-million-ton purported annual reductions in carbon dioxide (CO2) emissions claimed by the administration represents less than 2% of total U.S. CO2 emissions in 2020 and less than one day’s worth of world CO2 emissions.[54] Hence, even if the administration’s emissions reduction figure is accurate, it will have no measurable impact on climate change, especially as nations such as China, whose CO2 emissions are increasing and which accounts for almost one-third of all world emissions,[55] continue to increase their consumption of fossil fuels, including coal.

In addition, the prohibitive costs of offshore wind generation, along with the costs required to back up that generation to compensate for its inherent intermittency, will make electricity less affordable, especially in the Atlantic Coast states, where most of the offshore wind capacity will be located. Combined with policies mandating electrification of end-uses, such as space and water heat, as well as mandates for purchasing electric vehicles, the result will be to force millions of consumers and businesses to spend far more to meet their energy needs.

In addition, the prohibitive costs of offshore wind generation, along with the costs required to back up that generation to compensate for its inherent intermittency, will make electricity less affordable, especially in the Atlantic Coast states, where most of the offshore wind capacity will be located. Combined with policies mandating electrification of end-uses, such as space and water heat, as well as mandates for purchasing electric vehicles, the result will be to force millions of consumers and businesses to spend far more to meet their energy needs.

The resulting adverse economic impacts of these higher electricity costs—reduced spending available for investment and purchases of other goods and services—will reduce economic growth. Such reductions are almost certain to exceed the economic “gains” from massive subsidies for offshore wind, for the simple reason that, while robbing Peter to pay Paul benefits Paul, it harms Peter. It is impossible to subsidize one’s way to greater economic growth and prosperity. Subsidies transfer capital from higher-value uses that are supported by markets to lower-value ones that, but for those subsidies, would not be developed. (Otherwise, there would be no need for the subsidies.) That is the case for offshore wind, which is why the administration and Atlantic Coast states are offering offshore wind developers massive incentives.

Increasing subsidies and mandates for wind and solar power will undermine competitive wholesale electricity markets: prices will be zero or near zero when wind and solar are producing— and hugely expensive when they are not producing (see sidebar, How Intermittent Wind and Solar Power Affect Wholesale Power Markets).

Unfortunately, it is doubtful whether the basic economic and physical realities of the president’s offshore wind goal discussed in this report will change proponents’ minds. There are several reasons for this. One group of offshore wind proponents are surely well aware of the physical limitations that will prevent achievement of the 30,000-MW goal. Nevertheless, they stand to reap huge financial gains from the projects that are built. They may believe that addressing climate change is important, but their primary interest is exploiting green energy mandates for their own financial gain.

Indeed, in early 2021, the administration increased the financial benefits that project developers and financiers can obtain. Specifically, offshore wind projects will be able to collect both a production tax credit (PTC), currently about $24/MWh, and a 30% investment tax credit (ITC).[56] Previously, developers could collect only one of the credits. For example, the Danish and Spanish developers of Vineyard Wind will be able to recover an estimated $1.4 billion from U.S. taxpayers because of their eligibility to recover the ITC.[57]

A second group of offshore wind proponents may be characterized as “true believers.” For them, there is a looming climate catastrophe.[58] Preventing that catastrophe is more important than any other societal value, be it democracy, free speech, or existing laws. This group believes that preventing climate change requires massive investments in green energy, eliminating all fossilfuel consumption immediately, and other draconian changes to society. For this group, the extensive environmental damage caused by the mining and processing of rare-earth minerals,[59] or the child and slave labor that is used to mine cobalt in the Congo, is irrelevant.[60] Similarly irrelevant are concerns about adverse impacts on fisheries and endangered species, as well as higher energy costs and their impacts on the poor. This group is impervious to evaluating tradeoffs and, often, any rational argument.

About the Author

Jonathan Lesser is an adjunct fellow at the Manhattan Institute. As president of Continental Economics, Lesser has more than 30 years of experience working for regulated utilities, for government, and as a consultant in the energy industry. He has addressed economic and regulatory issues affecting energy in the U.S., Canada, and Latin America. Those issues include gas and electric utility structure and operations, generating asset valuation under uncertainty, cost-benefit analysis, mergers and acquisitions, cost allocation and rate design, resource investment-decision strategies, cost of capital, depreciation, risk management, incentive regulation, economic impact studies, and energy and environmental policies.

Lesser has prepared expert testimony and reports for utility commissions in numerous states; for the Federal Energy Regulatory Commission; for international regulators; and for commercial litigation cases. He has testified before Congress and many state legislative committees on energy policy and regulatory issues. Lesser is the author of numerous academic and trade-press articles and is a contributing columnist and editorial board member of Natural Gas & Electricity.

He earned a B.S. in mathematics and economics from the University of New Mexico and an M.A. and a Ph.D. in economics from the University of Washington.

Are you interested in supporting the Manhattan Institute’s public-interest research and journalism? As a 501(c)(3) nonprofit, donations in support of MI and its scholars’ work are fully tax-deductible as provided by law (EIN #13-2912529).